Sampling plan components consist of where to take samples, how many samples to take, what kind of samples (e.g., surface soil, air), and how to take samples and analyze them. We identified the general areas of where to take samples in Section 2.3, Sample Areas in VSP. In this section, we discuss where within the Sampling Area to locate the samples. We also discuss how many samples to take. The kind of samples to take-i.e., soil vs. groundwater, wet vs. dry, surface vs. core,-is determined during Step 3 of the DQO process (Define Inputs) and is not addressed directly in VSP. The Measurement Quality Objectives module in VSP (Section 5.4) deals with how the method selected for analytically measuring the sample relates to other components of the sampling plan.

VSP follows the DQO planning process in directing users in the selection of the components of the sampling plan. The first thing you must do is to select the type of problem for which the current data collection effort will be used to resolve. In VSP, we call this the Sampling Goal. The following types of problems are addressed currently in VSP. Future versions will expand on this list:

Sampling Goal |

Description |

Compare Average to Fixed Threshold |

Calculates number of samples needed to compare a sample mean or median against a predetermined threshold and places them on the map. This is called a one-sample problem. |

Compare Average to Reference Average |

Calculates number of samples needed to compare a sample mean or median against a reference mean or median and places them on the map. This is typically used when a reference area has been selected (i.e., a background area) and the problem is to see if the study area is equal to, or greater than, the reference area. This is called a two-sample problem because the data from two sites are compared to each other. |

Estimate the Mean |

Calculates number of samples needed to estimate the population mean and places them on the map. |

Construct Confidence Interval on Mean |

Calculates number of samples needed to find a confidence interval on a mean and places them on the map. |

Locate Hot Spots |

Use systematic grid sampling to locate a Hot Spot (i.e., small pockets of contamination). |

Show that at least some high % of the sampling area is acceptable |

Calculates number of samples needed to determine if contamination is present or if contamination is above or below a specified threshold. |

Combined Average and Individual Measurement Criteria |

Compares the results of two designs, to see which one requires the most samples to meet its sampling goals. |

Detect a Trend |

Determine whether a trend exists for a measurement of interest. |

Identify Sampling Redundancy |

Analyze data to determine whether sampling can be performed less frequently or in fewer locations without losing important trend or spatial information. |

Compare Proportion to Fixed Threshold |

Calculates number of samples needed to compare a proportion to a given proportion and places them on the map |

Compare Proportion to Reference Proportion |

Calculates number of samples needed to compare two proportions and places them on the map |

Estimate the Proportion |

Calculates number of samples needed to estimate the population proportion and places them on the map. |

Establish boundary of Contamination |

Determine whether contamination has migrated across the boundary. |

Find Target Areas and Analyze Survey Results (UXO) |

Traverse and detect an elliptical target zone using transect sampling. Calculates spacing for transects. Evaluates post-survey target detection. |

Post Remediation Verification Sampling (UXO) |

Assess degree of confidence in UXO presence. |

Sampling within a Building |

Allows sampling within rooms, zones, floors, etc., for various contamination release scenarios and end goals. |

Radiological Transect Surveying |

Traverse and detect a radiological hot spot using transect sampling. Calculates spacing for transects. Evaluates post-survey hot spot detection. |

Item Sampling |

Calculates the number of discrete items to sample to determine if the number of unacceptable items is above or below a specified threshold. |

Non-statistical sampling approach |

Allows samples to be added to the map without the guidance of statistical methods. |

This list of sampling goals available in VSP reflects the targeted interests and specific problems of our current VSP sponsors. Therefore, the available sampling designs within VSP are not an exhaustive list of designs you might find in a commercial statistical sampling package. Future versions will work toward a complete set of sampling design offerings.

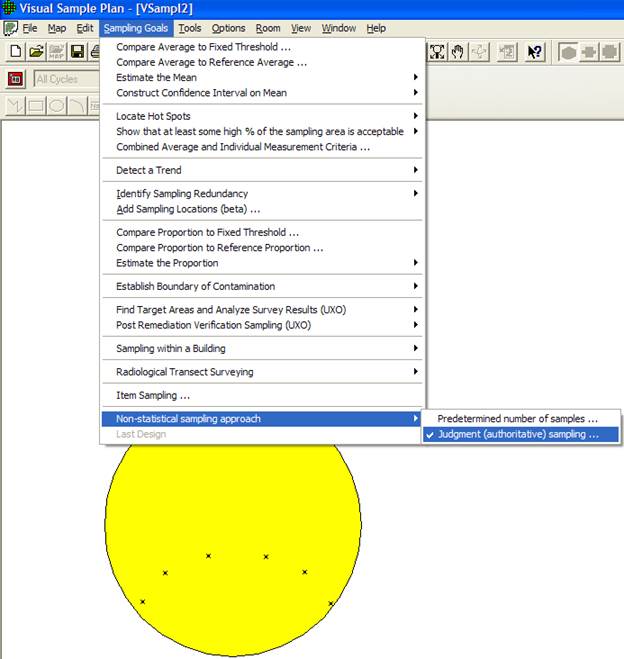

VSP lists "Non-statistical sampling approach" under Sampling Goals, but this is not really a goal. Under this category, VSP allows the user to specify a predetermined sample size and locate the samples judgmentally. Because VSP has no way of knowing how the sample size and sample locations were chosen, the sampling approach is considered to be "non-statistical" (i.e., no confidence can be assigned to the conclusions drawn from judgment samples).

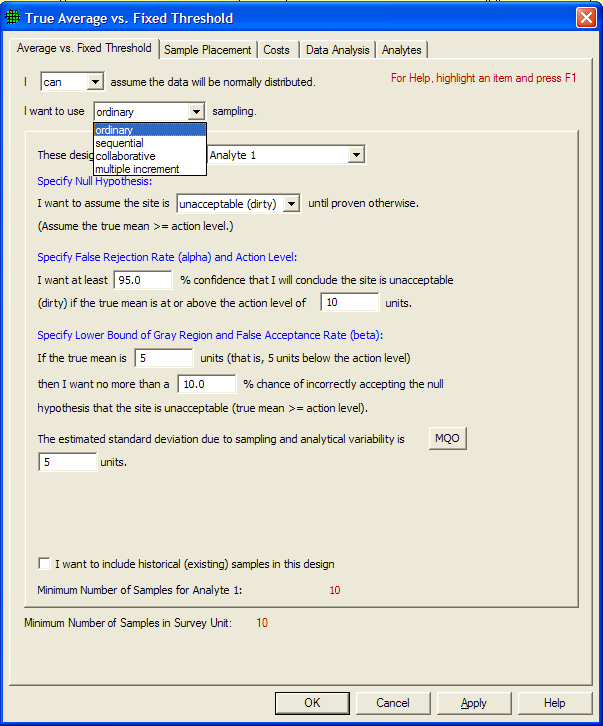

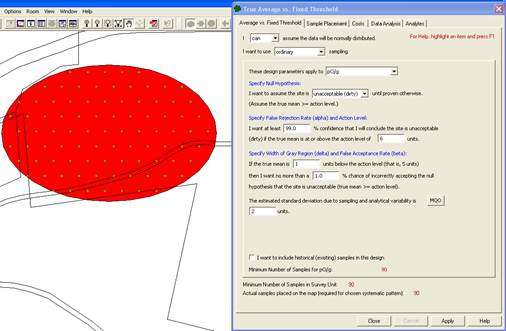

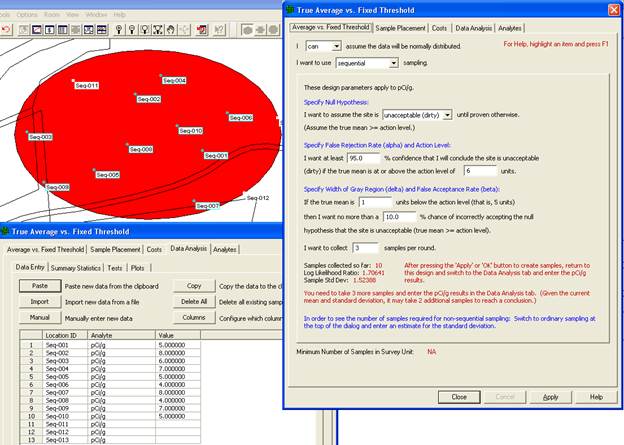

To give you an idea of how VSP threads from Sampling Goal to selection of a sampling design, Figure 3.1 shows the dialog for one of the goals, Compare Average to a Fixed Threshold. All endpoints from the Sampling Goal main menu result in a dialog box where the user provides inputs for the specific design selected. VSP allows only certain options and designs (e.g., simple random, systematic) under each goal. This is because VSP contains the algorithms for calculating sample number and locating samples for only certain goal-assumptions-statistical test or method sequences. Future versions of VSP will expand on the number and type of algorithms offered.

Figure 3.1. Dialog in VSP for Compare Average to Fixed Threshold

The current release of VSP offers several versions of the software (see Figure 2.1). Each version has a unique set of sampling designs available to the user - except General (all inclusive) VSP which contains all of the designs. Some of the designs available under each of the Sampling Goal menu items are unique to that goal, while other designs are available under multiple goals. Thus, the Sampling Goal you select determines which sampling design(s) will be available to you.

If a user is new to VSP, and is not looking for a specific sample design but rather has a general definition of the problem to be resolved with sample data, a good discussion of how to select a sampling design is in EPA's Guide for Choosing a Sampling Design for Environmental Data Collection (EPA 2002) http://www.epa.gov/quality/qa_docs.html. See Table 3-1 on pages 24-25 in that source for examples of problem types that one may encounter and suggestions for sampling designs that are relevant for these problem types in particular situations. Another guidance document, Multi-Agency Radiation Survey and Site Investigation Manual (MARSSIM) (EPA 1997) http://www.epa.gov/radiation/marssim/, also provides insight into how to select a sample design. The Expert Mentor in VSP may also be used to assist in selecting a sampling design by selecting Help > Expert Mentor and then clicking the Sampling Design Selection button.

One of the valuable ways to use VSP is to run through the various Goals and see what changes from one Goal to another, what sampling designs are available for each Goal, how designs perform, and what assumptions are required for each design. This trial and error approach is probably the best way to select a design that best fits your regulatory environment, unique site conditions, and goals.

An important point to keep in mind is the linkage between 1) the minimum number of samples that must be collected and where they are located, and 2) how you will analyze the sampling results to calculate summary values (on which you will base your decisions). The user must understand this linkage in order to select the appropriate design. Once the samples are collected and analyzed, the statistical tests and methods assumed in the sample size formulas and design may be used in the analysis phase, Data Quality Assessment (DQA).

Many of the designs in VSP contain a Data Analysis tab and allow sample results to be input into VSP so tests can be executed and conclusions drawn based on the results. See Section 5.6 for a discussion of Data Analysis within VSP.

We cannot discuss all the technical background behind the designs here, but the technical documentation for VSP gives sample size formulas used in VSP and provides references. The online help in VSP provides technical help and references. The reports that are available within VSP are a good source for definitions, assumptions, sample size formulas, and technical justification for the design selected. Finally, the VSP web site, http://vsp.pnl.gov/, has some technical documentation available, and allows download of the documents.

VSP allows both probability-based designs and judgmental sampling:

Probability-based sampling designs apply sampling theory and involve random selection. An essential feature of a probability-based sample is that each member of the population from which the sample was selected has a known probability of selection. When a probability based design is used, statistical inferences may be made about the sampled population from the data obtained from the sampled units. Judgmental designs involve the selection of sampling units on the basis of expert knowledge or professional judgment (EPA 2002, pp. 9-10).

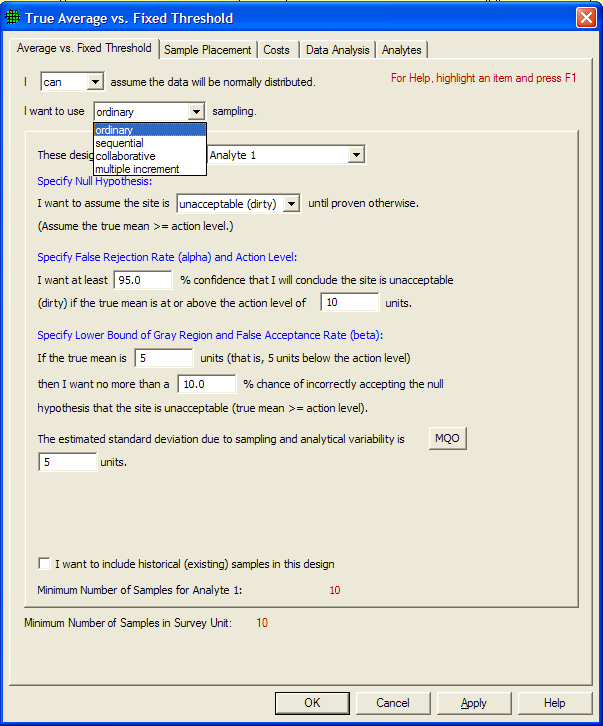

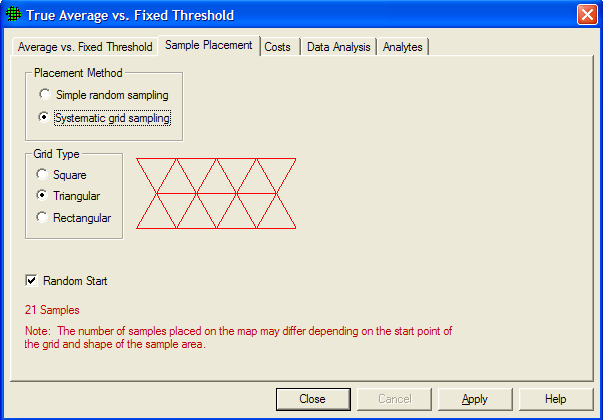

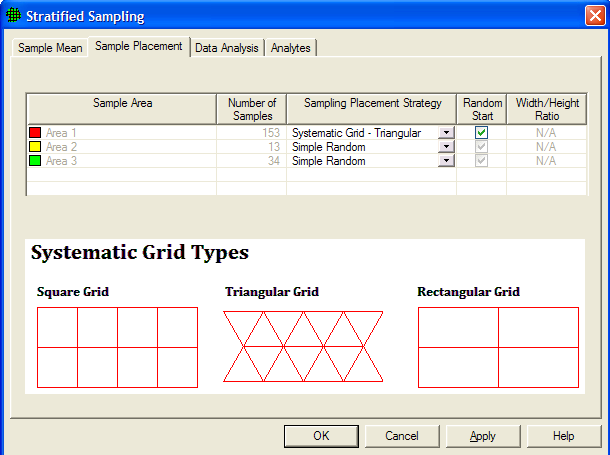

The design recommended by VSP depends on the sampling goal selected, assumptions made, and in the case of Ordinary Sampling, user input provided under the Sample Placement tab. VSP contains the following two- and three-dimensional designs. With exception tojudgment sampling, these are probability-based designs.

Figure 3.2 Sample Placement for Ordinary Sampling for Selecting Sample Placement Method and Type

Ordinary sampling - two Sample Placement options are available:

1. simple random sampling where sampling locations are selected based on random numbers, which are then mapped to the spatial locations, and

2. systematic grid sampling where sampling locations are selected on a regular pattern (e.g., on a square grid, on a triangular grid, or on a rectangular grid) with the starting location randomly selected. Sampling is done only at the node points of the grid. The grid pattern is selected under Grid Type. Figure 3.2 shows the dialog box for making input selections. You can see an example of the grid pattern selected in red to the right of the Grid Type options. You may specify Random Start or a fixed start for the initial grid point using the check box next to Random Start. Choosing Random Start will generate a new random starting location for the first grid location each time the Apply button is pushed. Once all selections have been made, press Apply.

stratified sampling - Strata or partitions of an area are made based on a set of criteria, such as homogeneity of contamination. Samples are drawn from each stratum according to a formula that accords more samples to more heterogeneous strata.

adaptive cluster sampling - An initial n samples are selected randomly. Additional samples are taken at locations surrounding the initial samples where the measurements exceed some threshold value. Several rounds of sampling may be required. Selection probabilities are used to calculate unbiased estimates to compensate for oversampling in some areas.

sequential sampling - Sequential designs are by their nature iterative, requiring the user to take a few samples (randomly placed) and enter the results into the program before determining whether further sampling is necessary to meet the sampling objectives.

collaborative sampling - The Collaborative Sampling (CS) design , also called "double sampling", uses two measurement techniques to obtain an estimate of the mean - one technique is the regular analysis method (usually more expensive), the other is inexpensive but less accurate. CS is not a type of sampling design but rather method for selecting which samples are analyzed by which measurement method.

ranked set sampling - In this two-phased approach, sets of population units are selected and ranked according to some characteristic or feature of the units that is a good indicator of the relative amount of the variable or contaminant of interest that is present. Only the mth ranked unit is chosen from this set and measured. Another set is chosen, and the m-1th ranked unit is chosen and measured. This is repeated until the set with the unit ranked first is chosen and measured. The entire process is repeated for r cycles. Only the m X r samples are used to estimate an overall mean.

sampling along a swath or transect - Continuous sampling is done along straight lines (swaths) of a certain width using geophysical or radiological sensors capable of continuous detection. Swath patterns can be parallel, square, or rectangular. The goal is to find circular or elliptical targets. This design contains the two elements of traversing the target and detecting the target. VSP application is for unexploded ordnance (UXO) and for detecting radiological hot spots.

sampling along a boundary - This design places samples along a boundary in segments, combines the samples for a segment, and analyzes each segment to see if contamination has spread beyond the boundary. If contamination has spread, VSP keeps extending the boundary until the sampling goals have been met.

multiple increment sampling - This design often arises because of the expense associated with analytical tests. A researcher would randomly take n increments and combine them together into r groups for analysis.

judgment sampling - You simply point and click anywhere in a sampling area. These sampling locations are based on the judgment of the user.

Because judgment sampling is not probability-based, users can bias the sampling results using this method. There is no basis in statistical theory for making confidence statements about conclusions drawn when samples are selected by judgment. However, some problem definitions might call for judgment sampling, such as looking in the most likely spot for evidence of contamination or taking samples at predefined locations. Figure 3.3 shows judgment sampling selected in VSP and six sampling locations selected manually.

Figure 3.3. Judgment Sampling in VSP

The inputs needed for VSP's sample-size calculations are decided upon during the DQO process. If you have not gone through the DQO process prior to entering this information, you can enter "best guess" values for each of the inputs and observe the resulting computed sample size. New inputs can be tried until a sample size that is feasible and/or within budget is obtained. This iterative method for using VSP is a valuable "what if" tool with which you can see the effect on sample size (and hence costs) of changing DQO inputs. However, be cautioned that all the DQO elements interact and have special meaning within the context of the problem. To be able to defend the sample size that VSP calculates, you must have a defensible basis for each of the inputs. There is no quick way to generate this defense other than going through Steps 1 through 6 of the DQO process.

The core set of DQO inputs that affect sample size for most of the designs are as follows:

Null Hypothesis Formulation - The null hypothesis is the working hypothesis or baseline condition of the environment. There must be convincing evidence in the data to declare the baseline condition to be false. VSP uses a default of "Site is Dirty" as the working hypothesis that must be disproved with convincing evidence from the data.

Type I Error Rate (Alpha) - This is called the false rejection rate in EPA's DQO guidance (EPA 2000a). This is the probability of rejecting a true null hypothesis. For the typical hypothesis test in which we assume the survey unit is dirty (above the action level), alpha is the chance a dirty site with a true mean equal to or greater than the Action Level will be released as clean to the public. In general, alpha is the maximum chance, assuming the DQO inputs are true, that a dirty site will be released as clean.

Type II Error Rate (Beta) - This is called the false acceptance rate in EPA's DQO guidance. This is the probability of not rejecting (accepting) a false null hypothesis. For the typical hypothesis test in which we assume the survey unit is dirty, beta is the chance a specific clean site will be condemned as dirty. Specifically, beta is the chance that a clean site with a true mean equal to or less than the lower bound of the gray region will be condemned as dirty. In general, beta is the maximum chance, outside the gray region, that a clean site will be condemned as dirty.

Width of Gray Region (Delta) - This is the distance from the Action Level to the outer bound of the gray region. For the typical hypothesis test in which we assume the survey unit is dirty, the gray region can be thought of as a range of true means where we are willing to decide that clean sites are dirty with high probability. Typically, these probabilities are 20% to 95%, i.e., from beta to 1 - alpha. If this region is reduced to a very small range, the sample size grows to be extremely large. Determining a reasonable value for the size of the gray region calls for professional judgment and cost/benefit evaluation.

Estimated Sampling Standard Deviation - This is an estimate of the standard deviation expected between the multiple samples. This estimate could be obtained from previous studies, previous experience with similar sites and contaminants, or expert opinion. Note that this is the square root of the variance. In one form or another, all the designs require some type of user-input as to the variability of contamination expected in the study area. After all, if the area to be sampled was totally homogeneous, only one sample would be required to completely characterize the area.

Other inputs are required by some of the designs, and other inputs are required for design parameters other than sample size. For example, the stratified designs require the user to specify the desired number of strata and estimates of proportions or standard deviations for each of the stratum. The UXO (unexploded ordinance) modules use Bayesian methods and require the user to input their belief that the study area contains UXO. When simulations are used, as in the post-survey UXO target detection, the user must input assumptions about the distribution of scrap or shrapnel in the target areas. In the discussions of the designs, we try to give an explanation of each input required of the user. If you are lost, use the VSP Help functions (See Section 2.7).

Note: The Help Topics function in VSP provides a description of each of the designs and its related inputs. You can also select the Help button on the toolbar, put the cursor on any of the designs on the menu and a description of the design and its inputs will appear in a Help window. In addition, pressing the Help button at the bottom of each design dialog will bring up a Help window that contains a complete explanation of the design. Finally, on each screen where input is required, highlight an item and press the F1 key for a description of that input item.

The next section contains a discussion of the inputs required by most of the designs available in the current release of VSP. The designs are organized by the Sampling Goal under which they fall. Not all options for all designs are discussed. Common design features (such as Costs, Historical Samples, MQO) that are found in multiple designs will not be discussed individually in this section but can be found in Section 5.0, Extended Features of VSP.

Comparing the average to a fixed threshold is the most common problem confronted by environmental remediation engineers. We present different forms the problem might take and discuss how VSP can be used to address each problem formulation.

We can continue where we left off in Section 2.3.3 with the Millsite.dxf map loaded. We selected a single Sample Area from the site. The Action Level for the contaminant of interest is 6 pCi/g in the top 6 in. of soil. Previous investigations indicate an estimated standard deviation of 2 pCi/g for the contaminant of interest. The null hypothesis for this problem is "Assume Site is Dirty" or HO: True mean = A.L.

We desire an alpha error rate of 1% and a beta error rate of 1%. According to EPA (2000a, pp. 6-10), 1% for both alpha and beta are the most stringent limits on decision errors typically encountered for environmental data. We tentatively decide to set the lower bound of the gray region at 5 pCi/g and decide a systematic grid is preferable.

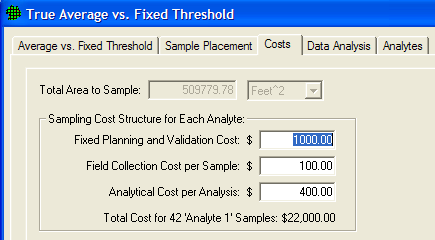

We will use VSP to determine the final width of the gray region and the number of samples required. Assume the fixed cost of planning and validation is $1,000, the field collection cost per sample is $100, and the laboratory analytical cost per sample is $400. We are told to plan on a maximum sampling budget of $20,000.

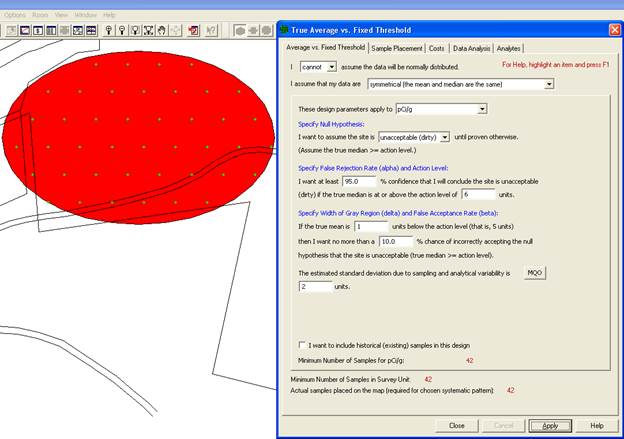

Case 1: We assume that the population from which we are sampling is approximately normal or that it is well-behaved enough that the Central Limit Theorem of statistics applies. In other words, the distribution of sample means drawn from the population is approximately normally distributed. We also decided that a systematic pattern for sample locations is better than a random pattern because we want complete coverage of the site.

(a)

(b) (c)

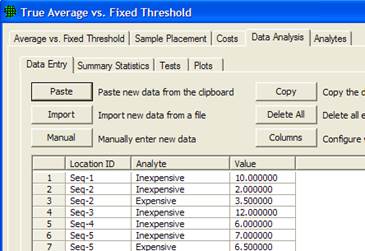

Figure 3.4. Input Boxes for Case 1 with Original Error Rates

VSP Solution 1: We start by choosing the VSP Sampling Goal option of Compare Average to Fixed Threshold. From the drop-downs, we select that we can assume the data will be normally distributed, and that we want to use ordinary sampling.For Sample Placement, we select Systematic grid sampling. For Grid Type we select Triangular with a Random Start. A grouping of the input dialogs is shown in Figure 3.4. Note that instead of inputting the alpha error rate directly, it is input as the confidence (100% - alpha%) in correctly accepting the null hypothesis.

We see that for our inputs, using a one-sample t-test will require taking 90 samples at a cost of $46,000. Clearly, we need to relax our error tolerances or request more funding.

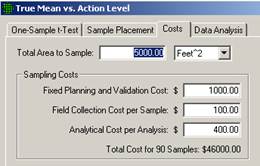

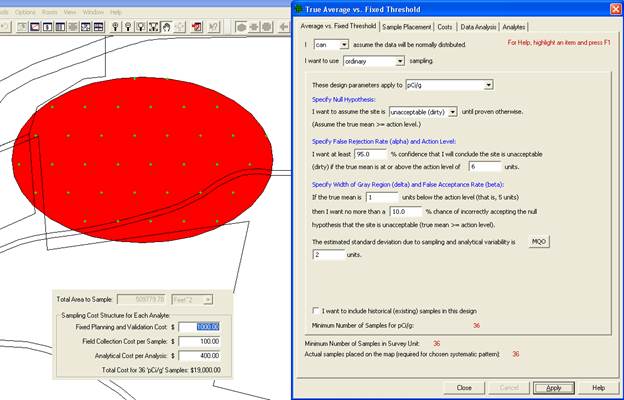

For the sake of argument, suppose all the stakeholders agree that an alpha error rate of 5% and a beta error rate of 10% are acceptable. Figure 3.5 reveals that those changes lead to a significant reduction in the sampling cost, now $19,000 for n =36 samples.

Are these new error rates justifiable? Only the specific context of each problem and the professional judgment of those involved can answer that question. What about the assumption that we will be able to use a parametric test, the one-sample t-test? Unless the population from which we are sampling is quite skewed, our new

Figure 3.5. Input Boxes for Case 1 with Increased Error Rates

sample size of n =36 is probably large enough to justify using a parametric test. Of course, once we take the data, we will need to justify our assumptions as pointed out in Guidance for Data Quality Assessment Practical Methods for Data Analysis (EPA 2000b, pp. 3-5).

Case 2: We now decide that we want to look at designs that may offer us cost savings over the systematic design just presented. We have methods available for collecting and analyzing samples in the field making quick turnaround possible. We want to be efficient and cost-effective and take only enough samples to confidently say whether our site is clean or dirty. After all, if our first several samples exhibit levels of contamination so high that there is no possible scenario for the average to be less than a threshold, why continue to take more samples? We can make a decision right now that the site needs to be remediated. Sequential designs, and the tests associated with them, take previous sampling results into account and provide rules specifying when sampling can stop and a decision can be made.

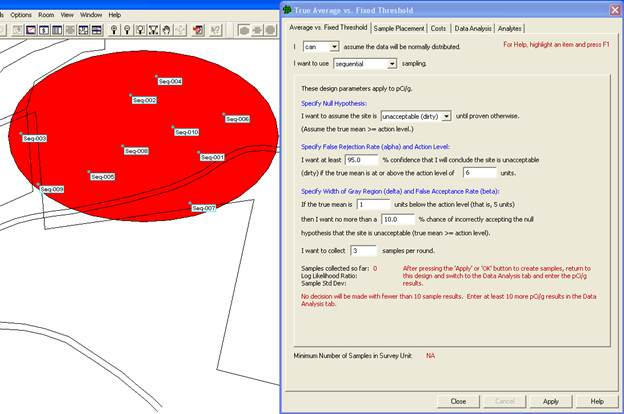

VSP Solution 2a: From VSP's main menu, select the Sampling Goal of Compare Average to a Fixed Threshold. From the drop-downs, select that we can assume the data will be normally distributed, and that we want to use sequential sampling. The dialog box in Figure 3.6 appears. We begin by entering the DQO parameters for Alpha, Beta, Action Level, etc., which in Figure 3.6 are shown in a sentence structure format. Next, enter the Number of Samples Per Round, shown here as 3. This parameter indicates how many samples you want to take each time you mobilize into the field. Each time you press the Apply button, VSP places a pattern of this many sampling locations on the map, except for the first round where at least 10 samples are needed to get an estimate of the standard deviation.

Figure 3.6. Dialog for Sequential Sampling (Standard Deviation Known) and Ten Locations Placed on the Map

In Figure 3.6, we see the results of pressing Apply. Ten locations are placed on the Map labeled "Seq-001, Seq-002, etc."

Once the sample results are available, click on the Data Analysis tab, go to the Data Entry sub-page, and enter the measurement values for those ten samples into the grid on the data input dialog. We enter these values as 5, 8, 6, 7, 5, 4, 8, 4, 7 and 5. Press the Apply button and in VSP you will see that three more samples have been generated. Return to the Average vs. Fixed Threshold tab. We now see in Figure 3.7 that the Number of Samples Collected as 10, and that VSP cannot accept or reject the null hypothesis on the basis of these samples and suggests that up to 2 additional samples may be needed to make a decision. (Note that VSP will not accept or reject the null hypothesis with fewer than 10 samples). VSP asks you to take 3 more samples, which are the three new samples placed on the map.

Figure 3.7. Data Input Dialog for Sequential Probability Ratio Test and Results from First Round of Sampling. Map View is shown in background.

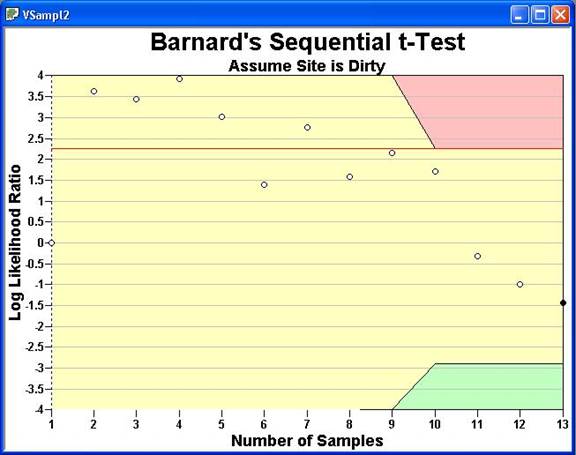

Switching over to the Graph View in Figure 3.8, we can see that in order to accept the null hypothesis that the site is dirty we need to take more than 10 samples. The open circles show the test statistic as the data are collected. The last 3 samples that appear on the graph are the next three samples, which can be entered in the Data Analysis tab's Data Entry sub-page as 6, 7, and 8. VSP now tells us that we can Accept the Null Hypothesis and conclude the site is dirty.

Figure 3.8. Graph View of Sequential Sampling

VSP Solution 2b. We have one other option for more cost-efficient sampling - reduce the analytic laboratory costs by taking advantage of measurement equipment that may be less accurate, but is less expensive. (Note that the two methods do not even have to measure the same thing as long as there is a linear correlation between them. For example, the expensive method may measure the concentration of Plutonium metal in soil and the inexpensive method may measure low-energy gamma radiation emitted by Americium in soil. This works because Americium is a daughter product of Plutonium decay). If we can still meet our DQOs (error levels, width of grey region) taking advantage of the less expensive equipment, we will save money.

It works like this: At 'n' field locations selected using simple random sampling or grid sampling, the inexpensive analysis method is used. Then, for some of the 'n' locations, the expensive analysis method is also conducted (nE). The data from these two analysis methods are used to estimate the mean and the standard error (SE: the standard deviation of the estimated mean). The method of estimating the mean and SE assumes there is a linear relationship between the inexpensive and expensive analysis methods. If the linear correlation between the two methods is sufficiently high (close to 1), and if the cost of the inexpensive analysis method is sufficiently less than that of the expensive analysis method, then Collaborative Sampling (CS) is expected to be more cost effective at estimating the population mean than if the entire measurement budget was spent on obtaining only expensive analysis results at field locations selected using simple random sampling or grid sampling.

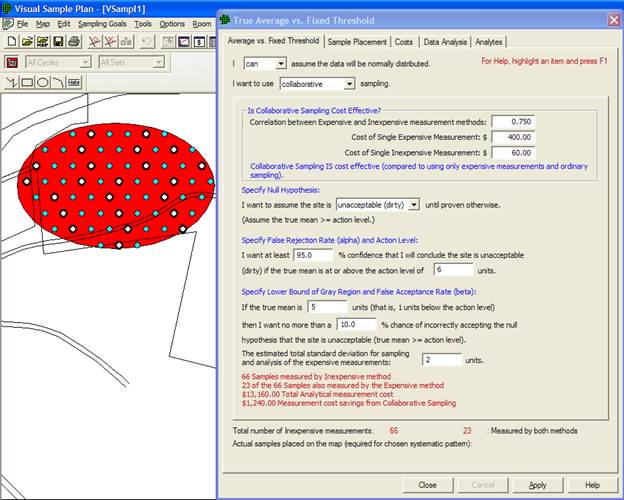

If Collaborative Sampling is chosen for the Sampling Goal of Compare Average to a Fixed Threshold the resulting Map View of the applied CS samples on the Millsite.dxf map are all shown in Figure 3.9.

Figure 3.9. Dialog Box for Collaborative Sampling and Map View of Applied CS Samples

The first set of inputs requested in the Data Input Dialog Box for CS are those needed to determine whether CS sampling is more cost effective than using only expensive measurements and simple random sampling. The first input required is the correlation coefficient between expensive and inexpensive measurements computed on the same set of samples. This is determined from data in prior studies or in a pilot study. The next two inputs are the cost estimates: the cost per unit of making a single expensive measurement, including the cost of sample collection, handling, preparation and measurement; and the cost per unit of making a single inexpensive measurement, including finding the field location and conducting the inexpensive analysis method.

The next set of inputs comprises the DQOs for the problem. Notice that these are the same inputs we used for Case 1 with increased error rates (see Figure 3.5) when VSP calculated a required sample size of 36. If all those 36 samples were analyzed with the expensive method, the total cost would be 36 x $400=$14,400. However, if we use CS and the same DQOs, VSP calculates we need to take 66 samples measured by the inexpensive method, and 23 of those 66 samples measured by the expensive method. This costs a total of 66 x $60=3960 plus 23 x $400=$9200 for a total of $13,160. This represents a $1,240 cost savings over the $14,400 we were going to spend. And the best part is we can achieve this cost savings and still meet our required error rates (i.e., the stated DQOs). Note: If VSP determined that CS was not cost effective, it would not have computed the two samples n and nE (66 and 23 samples, respectively) and reported only the number of samples that should be collected and analyzed using only the expensive method (36 samples).

Once we hit the Apply button at the bottom of the Dialog Box, VSP places all 66 samples on the Sample Area on the map. VSP color codes those sample locations where both methods should be used vs. the sample locations where just the inexpensive measurement method should be used. The applied color-coded samples are shown in the Map View insert in Figure 3.10.

We now exit the Dialog Box by clicking on the X in the upper right-hand corner of the display. We take our samples, use the appropriate measurement method, and return to the Data Analysis tab'sData Entry sub-page. The data values can be entered by typing them into this input screen, or by importing the data from a file such as an Excel spreadsheet (see Section 2.4.1 Importing Samples). Figure 3.10 shows the Dialog Box for entering data.

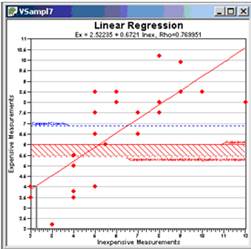

Note that the values we entered result in a Standard Deviation of 2.24 - we estimated 2, and the two sets of sample values have a correlation of .769 - we estimated .75. We are well above the correlation limit of .650 in order for collaborative sampling to be cost effective. If we bring up the Graph View in a second window (View > Graph), we see that VSP has taken the data values we input and plotted the expensive measurements versus the inexpensive measurements. This plot can be used to assess whether the assumption of a linear relationship between the expensive and inexpensive measurements required for the use of CS is reasonable. Note that the calculated Rho=.769 (the correlation coefficient) is listed at the top of the graph. The regression line is the solid red line through the points. The dashed blue line

Figure 3.10. Dialog Box for Entering CS Data Values and Graph View Showing where Data Values Fall on a Linear Regression Line

represents the computed mean (xcs). The horizontal red line represents the threshold value (Action Level).The bottom edge of the hashed red region represents the computed mean value below which the null hypothesis can be rejected.

VSP reports that based on the data values input, we can Accept the Null Hypothesis: Assume the Site is Dirty.

If we had chosen Simple Random Sampling rather than Systematic Grid Sampling on the Sample Placement tab, all the sample sizes would have been the same. The only difference would have been that the samples would have been placed on the Map in a grid pattern rather than randomly.

Case 3: We do not wish to assume that the population from which we are sampling is approximately normal.

VSP Solution 3a: The purpose of a MARSSIM sign test is to test a hypothesis involving the true mean or median of a population against an Action Level. Using this test for the mean assumes the distribution of the target population is symmetrical. When the distribution of the target population is symmetrical, the mean and the median are the same. When the distribution is not symmetrical, the Sign test is a true test for the median, and an approximate test for the mean. The appropriate use of the Sign Test for final status surveys is discussed in Multi-Agency Radiation Survey and Site Investigation Manual (MARSSIM) (EPA 1997). This document is currently available at http://www.epa.gov/radiation/marssim/. The input for the MARSSIM Sign Test is shown in Figure 3.11.

Figure 3.11. Dialog Box for the MARSSIM Sign Test

VSP Solution 3b: From VSP's main menu, select the Sampling Goal of Compare Average to a Fixed Threshold. From the drop-downs, select that we cannot assume the data will be normally distributed, and that our data are symmetrical (the mean and median are the same). Note that using this test for the mean assumes the distribution of the target population is symmetrical. A grouping of the input dialogs is shown in Figure 3.12.

Figure 3.12. Input Dialog for Wilcoxon Signed Rank Test

For our inputs, and assuming that we will use a nonparametric Wilcoxon Signed Rank test to analyze our data, VSP indicates that we are required to take 42 samples at a cost of $22,000. This is $3,000 more than the previous parametric case, given the same input parameters. Is the choice of a nonparametric test worth the extra $3,000 in sampling costs beyond what was required for the parametric one-sample t-test? VSP does not address that kind of question. Professional judgment is needed. You must make the decision based on the best available data, the consequences of decision errors, and legal and ethical considerations. If little pre-existing information is available, a pilot study to gain a better understanding of the characteristics of the population may be indicated, since a symmetric distribution of the target population is assumed.

For detailed documentation of the WSR test, please refer to the VSP Help Topic Wilcoxon Signed Rank Test.

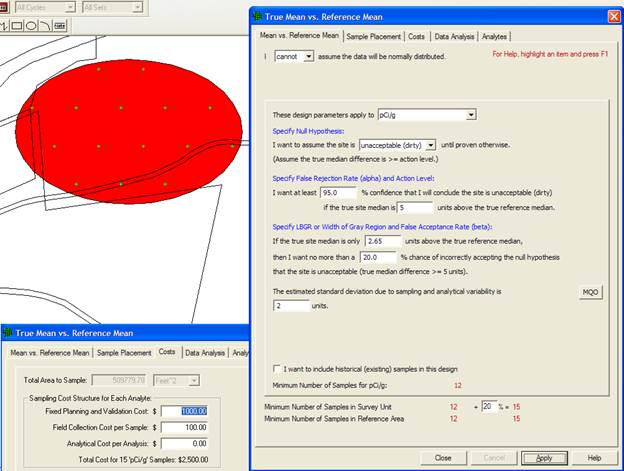

We again start with the Millsite.dxf map from Section 2.3.3 with a single Sample Area defined. The Action Level for the contaminant of interest is 5 pCi/g above background in the top 6 in. of soil. Background is found by sampling an appropriate reference area. Previous investigations indicate an estimated standard deviation of 2 pCi/g for the contaminant of interest. The null hypothesis for this problem is "Assume Site is Dirty" or HO: Difference of True Means = Action Level. In other words, the parameter of interest for this test is the difference of means, not an individual mean as was the case in the one-sample t-test.

We desire an alpha error rate of 1% and a beta error rate of 1%. We tentatively decide to set the lower bound of the gray region to 4 pCi/g above background, i.e., a difference of means of 4 pCi/g. Using VSP, we will determine the final width of the gray region and the number of samples required.

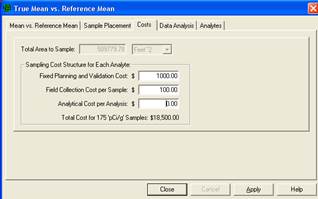

Assume that the fixed planning and validation cost is $1,000, the field collection and measurement cost per sample is $100, and the laboratory analytical cost per sample is $0 because we are able to justify the use of field measurements. We are told to plan on a maximum sampling budget of $20,000 for both the Reference Area and the Study Area.

Case 4: We assume that the populations we are sampling are approximately normal or that they are well-behaved enough so that the Central Limit Theorem of statistics applies. In other words, the distributions of sample means drawn from the two populations are approximately normally distributed. If that is the case, the distribution of the differences also will be approximately normally distributed. We also assume the standard deviations of both populations are approximately equal. In addition, we determine that a systematic grid sampling scheme is preferable.

VSP Solution 4a: We start by choosing from the main menu: Sampling Goals > Compare Average to Reference Average. A grouping of the input dialogs is shown in Figure 3.13.

Figure 3.13. Input Dialogs for Case 4 with Original Error Rates

We see that for our inputs, using a two-sample t-test will require taking 175 field samples in the Sample Area at a cost of $18,500. The sampling cost for the Reference Area also will be $17,500 (assuming the fixed costs will not be incurred a second time). The combined sampling cost of $36,000 is significantly beyond our budget of $20,000. What will be the result if we relax the error rates somewhat?

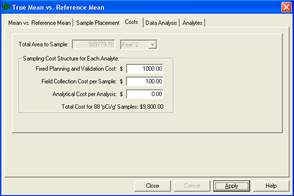

In Figure 3.14, by increasing both the alpha error rate and the beta error rate to 5%, the sampling cost for one area has decreased to $9,800 based on n =88 field samples. Thus, the new combined cost of $18,600 achieves our goal of no more than $20,000.

Can we justify these larger error rates? Again, only professional judgment using the best information related to the current problem can answer that question.

What about our planned use of a parametric test, the two-sample t-test? A sample size of 88 is large enough that we can probably safely assume the two-sample t-test will meet the assumption of normality for the differences of sample means. We should test this assumption after the data are collected.

What about the assumption of approximately equal standard deviations for the measurements in the Sample and Reference Areas? When we collect the data, we will need to check that assumption. See Guidance for Data Quality Assessment Practical Methods for Data Analysis (EPA 2000b, pp. 3-26) for the use of Satterthwaite's t-test when the standard deviations (or variances) of the two areas are not approximately equal.

Figure 3.14. Input Boxes for Case 4 with Increased Error Rates

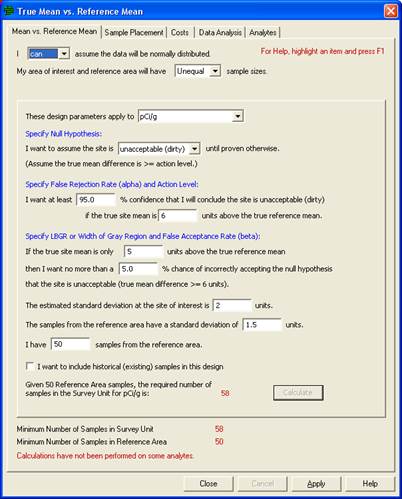

VSP Solution 4b: Taking the previous example, we now assume that the number of reference samples is fixed at 50, and the standard deviation for the reference samples is expected to be a slightly lower 1.5 pCi/g for the contaminant of interest. We want to calculate how many field samples to take while still meeting our parameters. We start by choosing from the main menu: Sampling Goals > Compare Average to Reference and use Unequal sample sizes. The input dialog is shown in Figure 3.15 after entering parameters and clicking Calculate. This module accounts for differences in sample sizes for reference and field samples, and also accounts for differences in standard deviations. VSP has run simulations and estimated that 58 field samples will be needed in addition to the 50 reference samples to achieve the desired alpha and beta levels to run a two-sample t-test.

Case 5: We now look at the case in which the nonparametric Wilcoxon Rank Sum (WRS) Test is planned for the data analysis phase of the project. VSP offers the MARSSIM version of the WRS Test. If the Sample and Reference population distributions are not symmetric, the WRS method tests the differences in the medians. If one wants to make a statement about the differences between means using the WRS test, it is required that the two distributions be symmetric so that the mean equals the median.

The Wilcoxon rank sum test is discussed in Guidance for Data Quality Assessment (EPA 2000b, pp. 3-31 - 3-34). The document can be downloaded from the EPA at: http://www.epa.gov/quality/qa_docs.html. It tests a shift in the distributions of two populations. The two distributions are assumed to have the same shape and dispersion, so that one distribution differs by some fixed amount from the other distribution. The user can structure the null and alternative hypothesis to reflect the amount of shift of concern and the direction of the shift.

Figure 3.15 Input Dialog for Case 4 with Unequal Sample Sizes and Unequal Standard Deviations

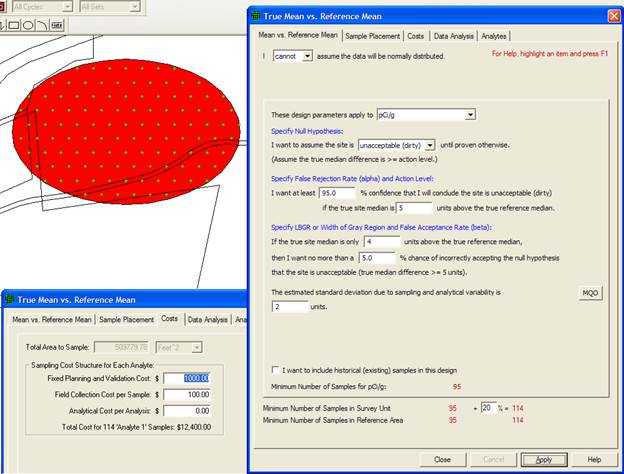

VSP Solution 5: We start by choosing from VSP's main menu Sampling Goals > Compare Average to Reference Average and select that you cannot assume the data are normally distributed. A grouping of the input dialogs is shown in Figure 3.16.

Shown in Figure 3.16, the input dialog for the MARSSIM WRS test allows the user to supply a percent overage to apply to the sample size calculation. MARSSIM suggests that the number of samples should be increased by at least 20% to account for missing or unusable data and for uncertainty in the calculated values of Sample Size, (EPA 1997, p. 5-29). With the extra 20%, 114 samples are required in both the Sample Area (i.e., Survey Unit or Study Area) and Reference Area.

The cost per area is now $12,400. The larger sample size of 114 instead of the previous sample size of 88 is probably not justified. However, professional judgment is needed to make the final decision.

Figure 3.16. Input Boxes for Case 5 Using Nonparametric Wilcoxon Rank Sum Test

For detailed documentation of the WSR test, please refer to the VSP Help Topic Wilcoxon Signed Rank Test.

The MARSSIM WRS test is used to test whether the true median in a Survey Unit population is greater than the true median in a Reference Area population. The test compares medians of the two populations because the WRS is based on ranks rather than the measurements themselves. Note that if both the Survey Unit and Reference Area populations are symmetric, then the median and mean of each distribution are identical. In that special case the MARSSIM WRS test is comparing means. The assumption of symmetry and the appropriate use of the WRS test for final status surveys is discussed in Multi-Agency Radiation Survey and Site Investigation Manual (MARSSIM) (EPA 2000). This document is currently available at: http://www.epa.gov/radiation/marssim/.

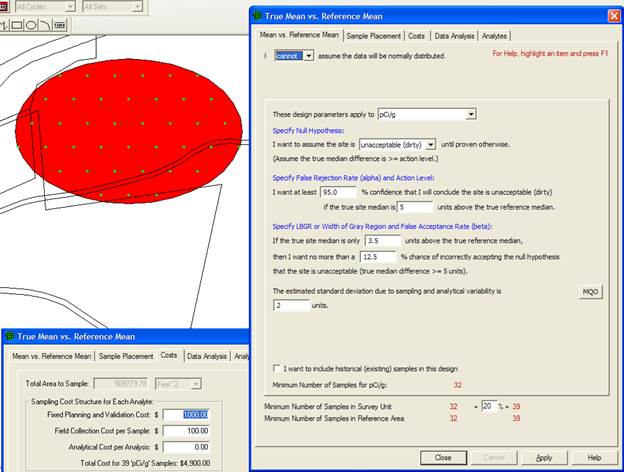

Case 6: Next, assume that the population from which we will be sampling is non-normal but symmetric and we again desire to use a nonparametric Wilcoxon rank sum test. However, we are limited to a total sampling budget for both areas of $10,000. By using VSP iteratively, we will adjust the various DQO input parameters and try to discover a sampling plan that will meet the new goals.

VSP Solution 6: Figure 3.17 shows that with an alpha of 5%, a beta of 12.5%, and a lower bound of the gray region of 3.5, the number of samples per area drops to 39. With a sampling cost of $3,900 for each sampling area, and assuming the fixed costs of $1,000 will only occur once, we now have a combined cost of $8,800 and thus meet our goal of $10,000.

Figure 3.17. Input Boxes for Case 6 Using Nonparametric Wilcoxon Rank Sum Test

Will relaxing the error tolerances and increasing the width of the gray region to meet the requirements of the smaller sampling budget be acceptable to all stakeholders in the DQO process? Again, it depends on the objectives and judgment of those involved in the process.

Case 7: Suppose our combined sampling budget is reduced to $5,000. Can VSP provide a sampling design that meets that goal?

VSP Solution 7: Figure 3.18 shows a design with just 15 samples per sampling area that meets the new sparse budget. We reduced the combined sampling cost, now $5,000, by increasing the width of the gray region to 2.35 pCi/g (lower bound of the gray region is 2.65 pCi/g) and by increasing the beta level to 0.20 (20%).

Figure 3.18. Input Boxes for Case 7 Using Nonparametric Wilcoxon Rank Sum Test

There are definite consequences of reducing sampling requirements to fit a budget. The consequences could include a greater chance of concluding that a dirty site is clean or a clean site is dirty. There is also a larger area of the gray region where you say you will not control (i.e., limit) the false acceptance error rate.

Is it justifiable to keep reducing the sampling budget in the above manner? Again, the answer depends on the specific problem. VSP, like most software, suffers from GIGO - Garbage In, Garbage Out. However, a responsible DQO process can provide valid information to VSP that overcomes GIGO and lets VSP help solve the current problem in an efficient manner.

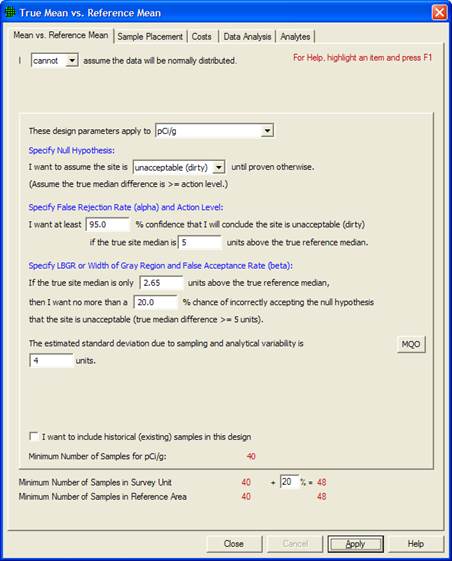

Case 8: Now we assume we have seriously underestimated the standard deviation. Suppose that instead of 2 pCi/g, it is really 4 pCi/g. Now how many samples should we be taking?

VSP Solution 8: Figure 3.19 shows the new sample size has jumped to 53, almost a four-fold increase over the 14 samples used in VSP Solution 7. For many sample-size equations, the number of required samples is proportional to the square of the standard deviation, i.e., the variance. Thus, an underestimate of the standard deviation can lead to a serious underestimate of the required sample size.

If we seriously underestimate the standard deviation of the measurements, what will be the practical implications of taking too few samples? Remember that we have as a null hypothesis "Site is Dirty." If the site is really clean, taking too few measurements means we may have little chance of rejecting the null hypothesis of a dirty site. This is because we simply do not collect enough evidence to "make the case," statistically speaking.

Figure 3.19. Input Boxes for Case 8 with Larger Standard Deviation

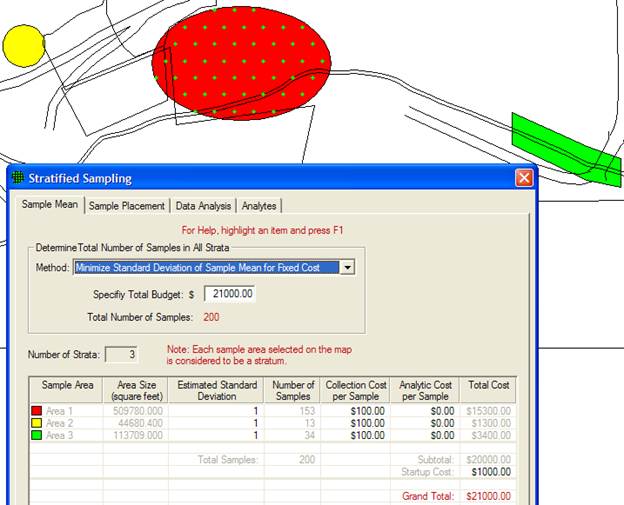

When the Sampling Goal is to Estimate the Mean > Data not required to be normally distributed, three design options are offered in VSP. None of the three requires the assumption of normality as the underlying distribution of units in the population. The options are:

Stratified sampling

Ranked set sampling

Collaborative sampling

For additional information on estimating the mean, please refer to the VSP Help Topic Estimate the Mean menu commands.

In Figure 3.20, we see the dialog box for entering parameters for stratified sampling. Prior to running VSP to calculate sample sizes for the strata, the user must have pre-existing information to divide the site into non-overlapping strata that are expected to be more homogeneous internally than for the entire site (i.e., all strata). They must be homogeneous in the variable of interest for which we want to calculate a mean. The strata are the individual user-selected Sample Areas and can be seen using Map View.

Figure 3.20. Dialog Box for Stratified Sampling for Estimating a Mean

With the Sample Areas selected (VSP shows total number of areas in Numbers of Strata), the dialog shows the initial values VSP assigns to the various inputs. The number of potential samples in each stratum is initially set at the number of 1-square-foot (or whatever units are used) units available to be sampled or approximately the area of the Sample Area (shown when the area is first selected). If the sample support is not a 1-square-foot volume, the user should change this to the correct value. The initial standard deviation between individual units in the stratum is assigned the value 1. It is in the same units as the mean. This is a critical value in the sample size calculation, so the user should make sure this is a good estimate. The sampling and measurement costs per sample in each stratum and the fixed costs are input in dollars. After entering the values for stratum 1, the user selects the next stratum from the drop-down list under Stratum #.

VSP allows simple random sampling or systematic within the strata. This is selected within the Sample Placement tab (Figure 3.21).

Figure 3.21. Sample Placement for Stratified Sampling for Estimating a Mean

The other inputs required by VSP pertain to the method the user wants to use for determining 1) the total number or samples in all strata and 2) the allocation of samples to strata. Methods are selected from the drop-down lists. VSP Help offers some insight into why one method might be selected over another, but the user should use the DQO process to flush out the site-specific conditions and project goals that will determine these inputs. Different inputs are required depending on which method is selected for determining the total number of samples. After you press Apply, the dialog shows in red the total number of samples and the number of samples in each stratum (use the pull-down Stratum # to switch between strata). You can see the placement of samples within strata by going to Map View.

For detailed documentation on Stratified Sampling, please refer to the VSP Help Topic Stratified Sampling for Estimating a Mean.

Ranked set sampling (RSS) is the second option for the Sampling Goal: Estimate the Mean > Data not required to be normally distributed. The number of inputs required for RSS is the most of any of the designs available in VSP. However, RSS may offer significant cost savings, making the effort to evaluate the design worthwhile. The VSP Help, the VSP technical report (Gilbert et al. 2002), and EPA (2002, pp. 79-111) are good resources for understanding what is required and how VSP uses the input to create a sampling design.

A simple example given here will explain the various input options. The user should have gone through the DQO process prior to encountering this screen because it provides a basis for inputs.

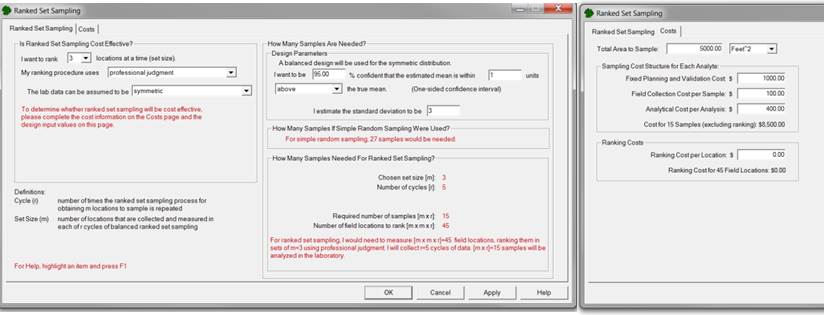

Under the tab Ranked Set Sampling, the first set of inputs deals with whether this design has any cost advantages over simple random sampling or systematic sampling where every unit that is sampled is measured and analyzed.

We select Symmetric for the distribution of lab data, thus telling VSP we think the lab data is not skewed so VSP should use a balanced design. A balanced design has the same number of cycles, say r =4, sampled for each of the say m =3 ranks (in this case the set size is 3). That is, a sample is collected at each of the four locations expected to have a relatively small value of the variable of interest, as well as at the four locations expected to have a mid-range value, and at four locations expected to have a relatively large value. An unbalanced design has more samples collected at locations expected to have large values. EPA says that a balanced design should be used if the underlying distribution of the population is symmetric (EPA 2002, p. 86).

We select Professional Judgment as the ranking method. We choose a set size of 3 from the pull-down menu. The set size we select is based on practical constraints on either our judgment or the field screening equipment available.

Note: VSP uses set size to calculate the factor by which the cost of ranking field locations must be less than lab measurement costs in order to make RSS cost-effective.

The next set of inputs required for RSS is information required to calculate the number of samples needed for simple random sampling. This value, along with cost information, is used to calculate the number of cycles, r. We say we want a one-sided confidence interval (we want a tight upper bound on the mean and are not concerned about underestimates of the sample mean), we want that interval to contain 95% of the possible estimates we might make of the sample mean, we want that interval width to be no greater than 1 (in units of how the sample mean is measured), and we estimate the standard deviation between individual units in the population to be 3 (in units of how the sample mean is measured). VSP tells us that if we have these specifications, we would need 27 samples if we were to take them randomly and measure each one in an analytical lab.

The box in the lower right corner of this dialog gives us VSP's recommendations for our RSS design: we need to rank a total of 45 locations. However, we need to send only 15 of those off to a lab for accurate measurement. This is quite a savings over the 27 required for simple random sampling. There will be r =5 cycles required.

Note: If we had chosen an unbalanced design, VSP would tell us how many times the top ranked location needed to be sampled per cycle. Also, the inputs for the confidence interval would change slightly for the unbalanced design.

All costs (fixed, field collection per sample, analytical cost for sending a sample to the lab, and ranking cost per location) are entered on the dialog box that appears when the Cost tab is selected. In Figure 3.22, we see the two dialog boxes for RSS.

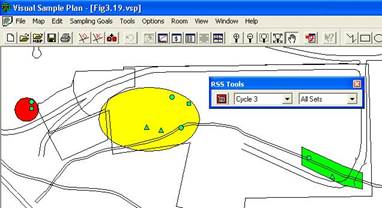

Once we press Apply, the RSS toolbar appears on our screen. The RSS toolbar lets us explore the locations to be ranked and the locations to be sampled and measured under Map View. VSP produces sample markers on the map that have different shapes and colors. The color of the marker indicates its cycle. The cycle colors start at red and go through the spectrum to violet. Selecting one of the cycles on the pull-down menu displays only the field locations for that cycle. In Figure 3.23, all the green field locations for Cycle 3 are shown. The shape of the marker indicates its set. Field sample locations for the first set are

Figure 3.22. Dialog Boxes for Ranked Set Sampling Design

Figure 3.23. Map of RSS Field Sample Locations for All Sets in Cycle 3, Along with RSS Toolbar

marked with squares, locations for the second set are marked with triangles, and so on. We show All Sets in Figure 3.23. For unbalanced designs, the top set is sampled several times, so a number accompanies those markers. Our example is for a balanced design so we do not see numbers.

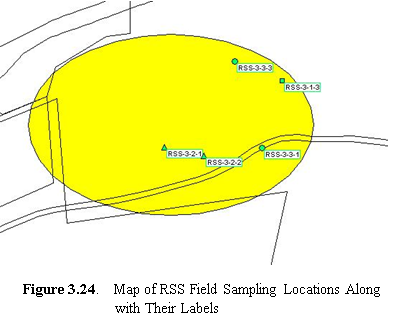

Ranked set field sampling locations are generated with a label having the following format: RSS-c-s-i

where c = the cycle number

s = the set number (the unbalanced design for this number is also incremented for each iteration of the top set)

I = a unique identifier within the set.

Use View > Labels > Labels on the main

menu or the AB button on the main toolbar (button also on the RSS

toolbar) to show or hide the labels for the field sample locations. Figure

3.24 shows the labels on the map for field sample locations associated

with Cycle 3, All Sets.

Use View > Labels > Labels on the main

menu or the AB button on the main toolbar (button also on the RSS

toolbar) to show or hide the labels for the field sample locations. Figure

3.24 shows the labels on the map for field sample locations associated

with Cycle 3, All Sets.

For detailed documentation on Ranked Set Sampling, please refer to the VSP Help Topic Ranked Set Sampling Design for Estimating a Mean.

The third design we discuss for a cost-effective option for estimating the mean when normality cannot be assumed is Collaborative Sampling (CS) - sometimes called Double Sampling. This design is applicable where two or more techniques are available for measuring the amount of pollutant in an environmental sample, for example a field method (inexpensive, less accurate) and a fixed lab method (expensive, more accurate). The approach is to use both techniques on a small number of samples, and supplement this information with a larger of number of samples measured only by the more expensive method. This approach will be cost-effective if the linear correlation between measurements obtained by both techniques on the same samples is sufficiently near 1 and if the less accurate method is substantially less costly than the more accurate method

Collaborative Sampling works like this: At n field locations selected using simple random sampling or grid sampling, the inexpensive analysis method is used. Then, for each of nE of the n locations, the expensive analysis method is also conducted. The data from these two analysis methods are used to estimate the mean and the standard error (SE: the standard deviation of the estimated mean). The method of estimating the mean and SE assumes there is a linear relationship between the inexpensive and expensive analysis methods.

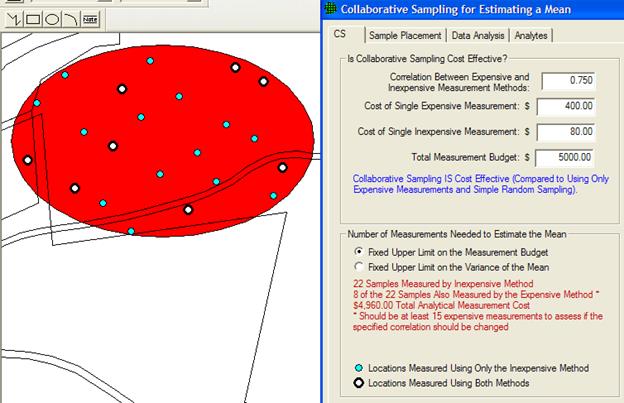

VSP has an extensive discussion of CS in the Help. CS is also discussed in Gilbert (1987), Chapter 9, where you can find an actual Case Study using CS. In Figure 3.25 we show the input screen for Collaborative Sampling.

Figure 3.25. Input Dialog Box for Collaborative Sampling for Estimating the Mean

For this example, we applied CS samples to an area on the Millsite map. After inputting the costs of each measurement technique, the total budget, and an estimate of the correlation between the two methods, VSP informs you whether or not CS is cost effective. For the vales we input, we see that it is cost effective. Then VSP uses the formulas discussed in the On-Line Help and the Report view to calculate two sample sizes, n (22), and nE (8). There are two options for optimizing the values of n and nE that the VSP user must select from:

estimate the mean with the lowest possible standard error (SE: the standard deviation of the estimated mean) under the restriction that there is a limit on the total budget, or

estimate the mean under the restriction that the variance of the estimated mean (square of the SE) does not exceed the variance of the mean that would be achieved if the entire budget were devoted to doing only expensive analyses.

We select the first option. VSP calculates that we need to take 22 samples and measure them with the inexpensive method, 8 of which are also measured using the more expensive methods. However, we get a warning message that we should be taking at least 15 measurements where we use both methods in order for VSP to assess whether our initial estimate of a 0.75 linear correlation coefficient is correct. Note that after we hit the Apply button, we see the sampling locations placed on the Sample Area we selected (Millsite.dxf used for this example).

As with Collaborative Sampling for Hypothesis Testing discussed in Section 3.2.1, VSP allows us to input the results of the sampling to verify that the computed correlation coefficient is close to the estimated correlation coefficient used to calculate the sample sizes. Data Results are input in the dialog box that appears after selecting the Data Analysis tab and the Data Entry sub-page. VSP calculates the estimated mean and standard deviation of the estimated mean once the data values are input.

For detailed documentation on Collaborative Sampling, please refer to the VSP Help Topic Collaborative Sampling for Estimating a Mean.

Adaptive cluster sampling is appropriate if we can assume the target population is normally distributed: Sampling Goal > Estimate the Mean > Can assume data will be normally distributed > Adaptive Cluster Sampling. Because adaptive designs change as the results of previous sampling become available, adaptive cluster sampling is one of the two VSP designs that require the user to enter sample values while planning a sampling plan. (The other design that requires entering results of previous sampling is sequential sampling; see Section 3.2.1). The VSP Help, the VSP technical report (Gilbert et al. 2002), and the EPA (2001, pp. 105-112) are good resources for understanding what is required and how VSP uses the input to create a sampling design. A simple example here will explain the various input options. The user should have gone through the DQO process prior to encountering this screen because it provides a basis for inputs.

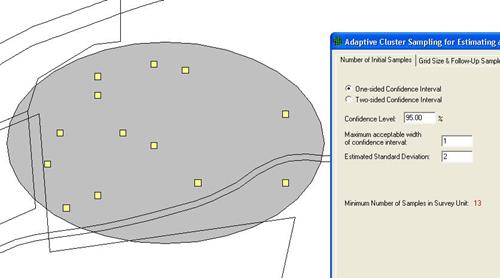

The screen for entering values in the dialog box is displayed by selecting the tab Number of Initial Samples. Adaptive cluster sampling begins by using a probability-based design such as simple random sampling to select an initial set of field units (locations) to sample. To determine this initial sample number, either a one-sided or two-sided confidence interval is selected. We select One-sided Confidence Interval and enter that we want a 95% confidence that the true value of the mean is within this interval. We want an interval width of at least 1 and we estimate the standard deviation between individual units in the population to be 2 (units of measure for interval width and standard deviation is same as that of individual sample values). VSP returns a value of 13 as the minimum number of initial samples we must take in the Sample Area. In Figure 3.26, we can see the 13 initial samples as yellow squares on the map.

Figure 3.26. Map of Sample Area with Initial Samples for Adaptive Cluster Sampling Shown as Yellow Squares, Along with Dialog Box

Figure 3.27. Dialog Input Box for Entering Sample Measurement Values and Labels for Initial Samples in Adaptive Cluster Sampling

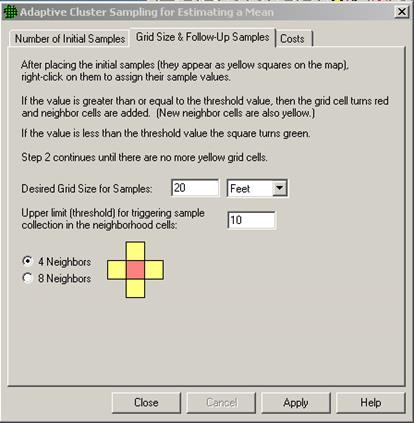

Select tab Grid Size & Follow-Up Samples on the Adaptive Cluster for Estimating a Mean dialog box. Enter the desired Grid Size for Samples, shown here as 20 ft, and an upper threshold measurement value that, if exceeded, triggers additional sampling. We chose 10 as the threshold. We have a choice of how to expand sampling once the threshold is exceeded: 4 nearest neighbors or 8 nearest neighbors. We choose 4. The dialog box is shown as the insert in Figure 3.28. The grid units can be orientated at different angles by selecting Edit > Sample Areas > Set Grid Angle and Edit > Sample Areas > Reset Grid Angle from the main menu.

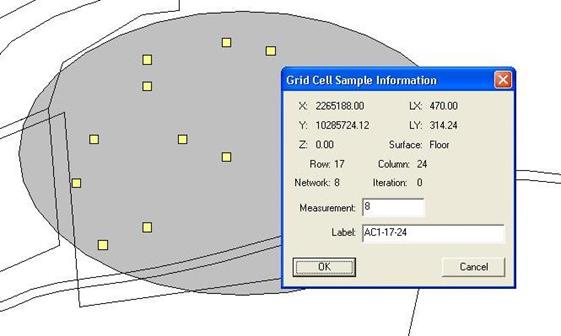

The user now enters the analytical measurement results for the initial 13 sampling units. (Adaptive cluster sampling is most useful when quick turnaround of analytical results is possible, e.g., use of field measurement technology.) Place the mouse directly over each sample and right-click. An input box appears as shown in Figure 3.27. Enter a measurement value (shown here as 8) and, if desired, a label (shown here as AC1-25-62). Press OK. Enter another sample value and continue until all 13 sample values have been entered.

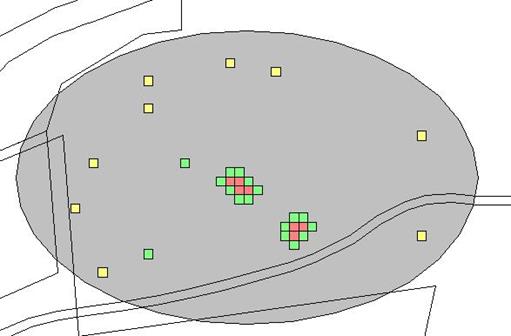

Once Measurement values have been entered, the yellow squares turn to either green, indicating the sample did not exceed the threshold, or red, indicating the sample exceeded the threshold. The red samples are surrounded with additional yellow squares that now must be sampled. This process continues until there are no more yellow grid cells. In Figure 3.29, we see examples of green, single yellow, red surrounded by yellow, and red surrounded by green. Sampling and measurement continues until all the initial samples are green or red and all the added samples are green or red.

Figure 3.28. Dialog Input Box for Entering Grid Size and Follow-up Samples

Figure 3.29. Examples of Combinations of Initial and Follow-up Samples from Adaptive Cluster Sampling

Costs are entered using the Cost tab on the dialog box. The Report for adaptive cluster sampling shows the total cost for all the initial samples plus follow-up samples and provides an (unbiased) estimate of the mean and its standard error. Refer to VSP's Help for a complete discussion of adaptive cluster sampling.

For detailed documentation on Adaptive Cluster Sampling, please refer to the VSP Help Topic Adaptive Cluster Sampling for Estimating a Mean.

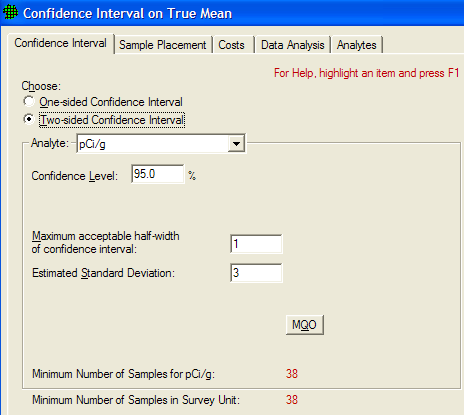

If the VSP user wants a confidence interval on the true value of the mean, not just a point estimate of the mean as calculated in Section 3.2.3, the user selects Sampling Goal > Construct Confidence Interval on the Mean. When the data can be assumed to be normally distributed, the user can choose Ordinary Sampling, Collaborative Sampling, or Multiple Increment Sampling.

For Ordinary Sampling, four DQO inputs are required:

whether a one- or two-sided interval is desired,

the confidence you want to have that the interval does indeed contain the true value of the mean,

the maximum acceptable half-width of confidence interval, and

an estimate of the standard deviation between individual units of the population.

Figure 3.30. Dialog Input Box for Calculating a Confidence Interval on the Mean using Ordinary Sampling

The two-sided confidence interval, smaller interval width sizes, and larger variation generally require more samples. In Figure 3.30, we see an example of the design dialog for the Confidence Interval on the Mean sampling goal for Ordinary Sampling, along with the recommended sample size of 38 that VSP calculated.

If the user has more than one type of sample measurement method available, Collaborative Sampling should be explored to see if cost savings are available. Though not shown here, the inputs for Collaborative Sampling for Confidence Interval are similar to those in Figure 3.29, with the added cost inputs required to determine if Collaborative Sampling is cost effective (see discussion of Collaborative Sampling in Section 3.2.3.3). Note that under the sampling goal of Construct Confidence Interval on the Mean, Collaborative Sampling is put under the assumption of "normality", while for the sampling goal of Estimate the Mean, Collaborative Sampling is put under the assumption of "Data not required to be normally distributed." This is because for Estimating the Mean, the calculation of sample size n is based on restrictions on the budget or restrictions on the variance which make no distributional assumptions; while for Construct Confidence Interval on the Mean, the calculation of n is based on percentiles of the standard normal distribution.

If samples will be combined for analysis, then Multiple Increment Sampling can be selected. This method has additional inputs concerning between increment and within increment standard deviations, and the number of samples being combined.

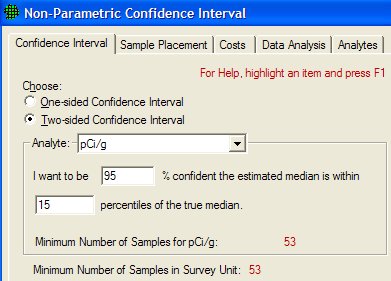

If we cannot assume data will be normally distributed, VSP computes a non-parametric confidence interval. The user specifies a one or two-sided confidence interval, and the percent confidence they wish to attain to be within a specified number of percentiles of the true mean (Figure 3.31).

Figure 3.31. Dialog Input Box for Calculating a Non-Parametric Confidence Interval on the Mean using Ordinary Sampling

For detailed documentation on how to construct confidence interval on mean,

please refer to the VSP Help Topic Construct

Confidence Interval on Mean menu commands.

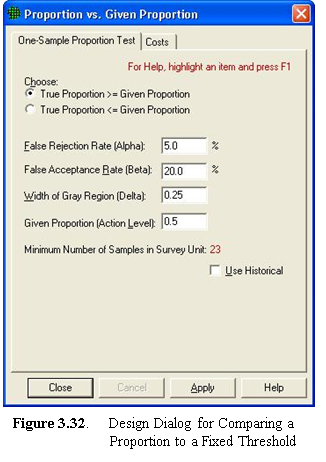

For comparing a proportion to a threshold (i.e., a given proportion), the designs available in VSP do not require the normality assumption. A one-sample proportion test is the basis for calculating sample size. The inputs required to calculate sample size are shown in the design dialog in Figure 3.32. The DQO inputs are similar to those for comparing an average to a fixed threshold, but since the variable of interest is a proportion (percentage of values that meet a certain criterion or fall into a certain class) rather a measurement, the action level is stated as a value from 0.01 to 0.99. Based on the inputs shown in Figure 3.32, VSP calculates that a sample size of 23 is required.

For detailed documentation on compare proportion to fixed threshold, please refer to the VSP Help Topic Compare Proportion to Fixed Threshold.

3.2.6 Compare Proportion

to Reference Proportion

3.2.6 Compare Proportion

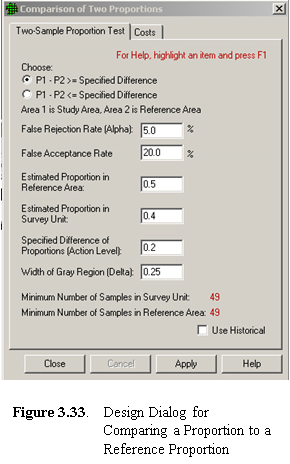

to Reference ProportionVSP formulates this problem as an environmental cleanup problem in which we have the proportion of contamination within a survey unit (Population 1) and we want to see if the difference between it and a reference area (Population 2) is greater (or less than) a specified difference. This specified difference becomes the action level. If we select the first formulation of the problem (P1 - P2 = specified difference), we must enter a lower bound for the gray region. If we select the second formulation (P1 - P2 = specified difference), we must enter an upper bound for the gray region. We must also enter our best guess of what we think the proportion of contamination is in both the survey unit and the reference unit. These two values are required to estimate the standard deviation of the proportions, which are then used as inputs to the sample size formula.

Note that if the proportion of interest is the proportion of positive units in the environment, say the proportion of one-acre lots within a development area that have trees, then we need to select the null hypothesis that affords us the greatest protection against a false acceptance. In Figure 3.33, we see an example of the design dialog for this sampling goal. VSP calculates that we need 49 samples in the survey unit and 49 samples in the reference area for this set of inputs.

If no previous information is available on which to estimate the proportions in the survey unit or reference area, use 0.5 because at that value the sample sizes are the largest (i.e., the most conservative).

Similar to the designs available for estimating the mean, VSP offers stratified sampling for the sampling goal of estimating the proportion because a stratified design may be more efficient than either simple random sampling or systematic sampling. Designs and sample size formulas for a simple random selection of samples are not in the current release of VSP but can be found in standard statistics textbooks.

There will be occasions when it is necessary to determine with a specified high probability that no hot spots of a specified size and shape exist in the study area. A hot spot is a local contiguous area that has concentrations that exceed a threshold value. Initially, the conceptual site model should be developed and used to hypothesize where hot spots are most likely to be present. If no hot spots are found by sampling at the most likely locations, then VSP can be used to set up a systematic square, rectangular or triangular sampling grid to search for hot spots. Samples or measurements are made at the nodes of the systematic grid. The VSP user specifies the size and shape of the hot spot of concern, the available funds for collecting and measuring samples, and the desired probability of finding a hot spot of critical size and shape. Either circular or elliptical hot spots can be specified.

The VSP user can direct VSP to compute one or more of the following outputs:

The number and spacing of samples on the systematic sampling grid that are required to achieve a specified high probability that at least one of the samples will fall on a circular or elliptical hotspot of the specified size.

The probability that at least one of the samples collected at the nodes of the specified systematic sampling grid will fall on a circular or elliptical hot spot of specified size.

The smallest size circular or elliptical hot spot that will be detected with specified high probability by sampling at the nodes of the systematic sampling grid.

The basic structure for these problems is that there are three variables (grid spacing, size of hot spot, and probability of hitting a hot spot). You can fix any two of them and solve for the remaining variable.

The other unique feature of the hot spot problem is that there is only one type of error-the false negative or alpha error. VSP asks for only one probability for some formulations of the problem-the limit you want to place on missing a hot spot if it does indeed exist. The other error, saying a hot spot exists when it doesn't, cannot occur because we assume that if we do get a "hit" at one of the nodes, it is unambiguous (we hit a hot spot). We define hot spots as having a certain fixed size and shape, i.e., no amorphous, contouring hot spots are allowed. The hot spot problem is not a test of a hypothesis. Rather, it is a geometry problem of how likely it is that you could have a hot spot of a certain size and shape fitted within a grid, and none of the nodes fall upon the hot spot.

All the input dialog boxes for the Hot Spot problem will not be shown in this user's manual. VSP's Help and the textbook Statistical Methods for Environmental Pollution Monitoring (Gilbert 1987) are good resources for a complete discussion of the Hot Spot problem. We demonstrate a common formulation of the problem-find the minimum number of samples to find a hot spot of a certain size, with specified confidence of hitting the hot spot.

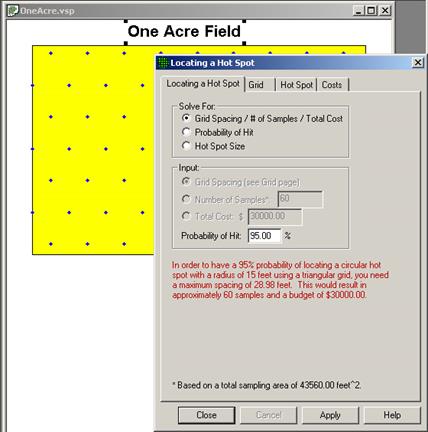

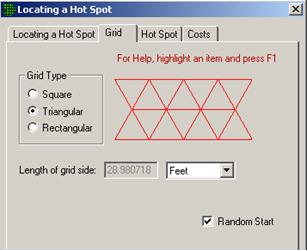

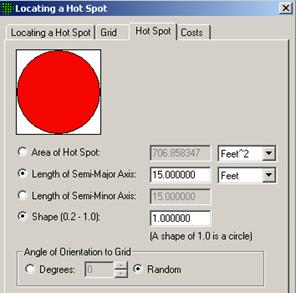

Problem Statement: A site has one Sample Area of one acre (43,560 square feet). We wish to determine the triangular grid spacing necessary to locate a potential circular pocket of contamination with a radius of 15 feet. We desire the probability of detecting such a hot spot, if it exists, to be at least 95%. The fixed planning and validation cost is $1,000. The field collection cost per sample is $50, and the laboratory analytical cost per sample is $100. Assume that the budget will be provided to support the sampling design determined from these requirements.

Case 9: We assume that the assumptions listed in Gilbert (1987, p. 119) are valid for our problem. We specify a hit probability of 95%, a shape of 1.0 (circular), and a radius (Length of Semi-Major Axis) of 15 feet. We will let VSP calculate the length of the side of the equilateral triangular grid needed for these inputs.

VSP Solution 9: First, open the file OneAcre.vsp using VSP Main Menu option File > Open Project. This is a VSP-formatted project file and it contains a previously defined Sample Area of the entire acre. Next, from the VSP Main Menu select Sampling Goals > Locating a Hot Spot > Assume no false negative errors. A grouping of the input dialogs for the four tabs: Locating Hot Spot, Grid, Hot Spot, and Costs are shown in Figure 3.34.

The recommended length of grid side is shown in the dialog box for Locating a Hot Spot, Solve for Grid Spacing. It is about 28.98 feet or, rounding up, a 30-foot triangular grid.

Note: For this set of inputs, VSP will always give the length of the triangular grid as 28.98 feet. The Calculated total number of samples in the Report View is always 60 for this set of inputs. However, the Number of samples on the map changes as you repeatedly press the Apply button. This occurs whenever the Random Start check box in the dialog box tabbed Find Grid is checked. Because the starting point of the grid is random, the way in which the grid will fit inside the Study Area can change with each new random-start location. More or fewer sampling locations will occur with the same grid size, depending on how the sampling locations fall with respect to the Sample Area's outside edges.

Figure 3.34. Input Boxes for Case 9 for Locating a Hot Spot

The input dialog boxes and report for the hot spot problem have some unique features:

Placing the cursor in the Length of Semi-Major Axis on the Hot Spot tab and right-clicking displays a black line on the picture of the circle for the radius.

Shape controls how "circular" the hot spot is. Smaller values (0.2) result in a more elliptical shape; 1.0 is a perfect circle.

The user can specify the Area of the hot spot or the Length of the Semi-Major Axis. Both fields have pull-down menus for selecting the unit of measurement.

The Report provides additional information on the design such as the number of samples (both "on the map" and "calculated") and grid area.

The Hot Spot Sampling Goal takes into account the Total Area to Sample (see this field on the Cost tab) when calculating total number of samples. Many of the other designs use the standard deviation to control sample size.

Selecting Sampling Goals > Locating a Hot Spot > Account for false negative errors provides an option for entering a false negative rate for each sample (the probability each contaminated sample will not be detected). For this option, only circular (Shape=1) hot spots may be used.

Selecting Sampling Goals > Locating a Hot Spot > Using existing locations provides an option for adding additional sampling locations to some previously collected to minimize the locations where circular hot spots may exist on a site.

For further information on locating hotspots, please refer to the VSP Help Topic Detecting Hot Spots.

This Sampling Goal originated from specific unexploded ordinance (UXO) problems faced by the Department of Defense. The sampling designs the VSP developers came up with to address these problems are somewhat specialized. UXO methods are covered in Chapter 7.

This Sampling Goal also originates from UXO Problems, and is covered in Chapter 7.

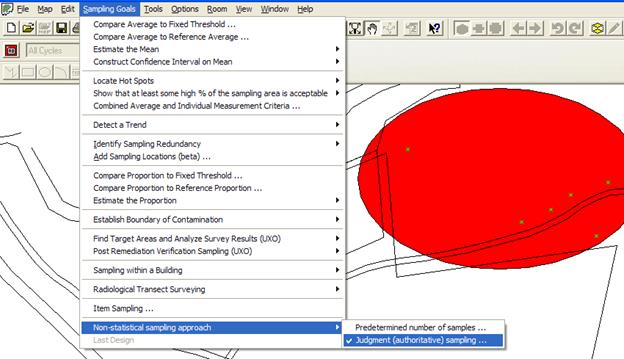

VSP allows the user to directly place samples in a Sample Area without going through the Sampling Goals and the DQO Process. If the user has a pre-determined number of samples, possibly obtained from a prior DQO study, VSP allows the user to input a sample size and place the samples within the Sample Area using either a random design or a systematic design. Menu selection Sampling Goals > Non-Statistical Sampling Approach > Predetermined Number of Samples brings up a simple dialog box where the user can input any value for Number of Samples, and by hitting the Apply button, the samples are placed in the Sample Area according to the design specified (random or systematic).

VSP allows the user to manually place samples on a Map within a selected Sample Area by selecting Sampling Goals > Non-Statistical Sampling Approach > Judgment (authoritative) Sampling. This option is available only if View > Map is selected and a Sample Area is defined. Judgment Sampling is a toggle switch. When it is turned on, any time the user clicks on the map, a sample marker is placed at that location. Judgment samples can be added to a blank Map or to an existing design. The Type is "Manual" (see View > Coordinates). Manual samples may also be added by typing the coordinates (x, y) on the keyboard.

In Figure 3.35, 6 samples have manually been added using Judgment Sampling.

Figure 3.35. Judgment Sampling with Six Sampling Locations Added Manually

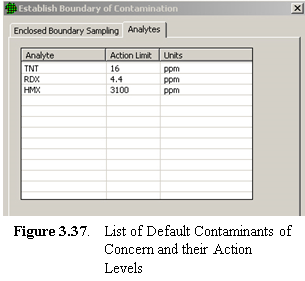

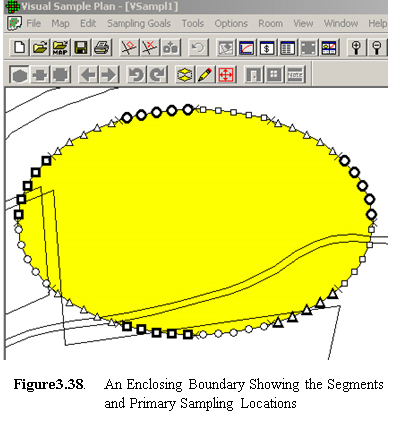

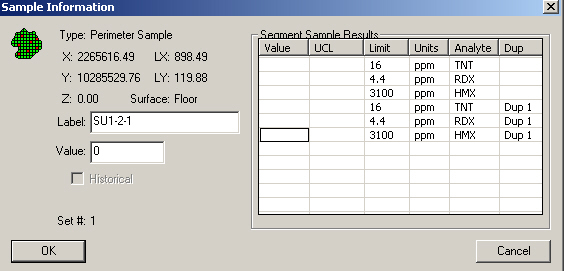

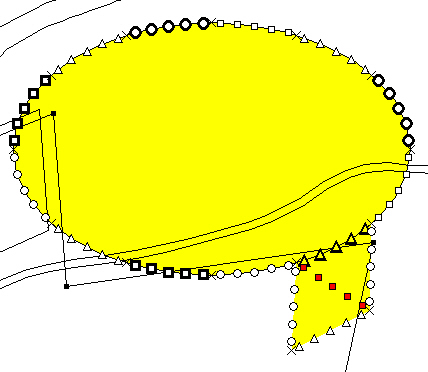

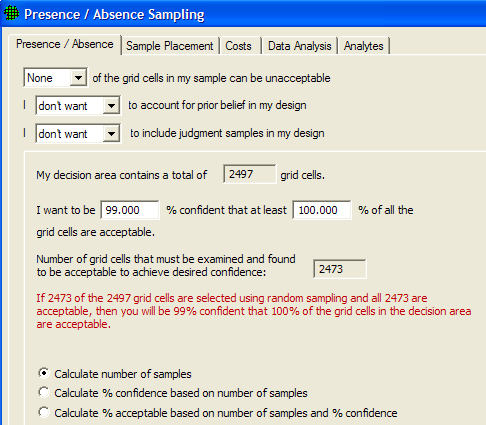

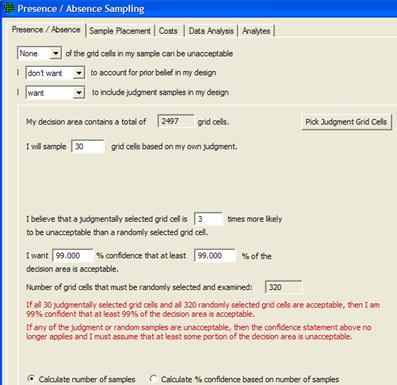

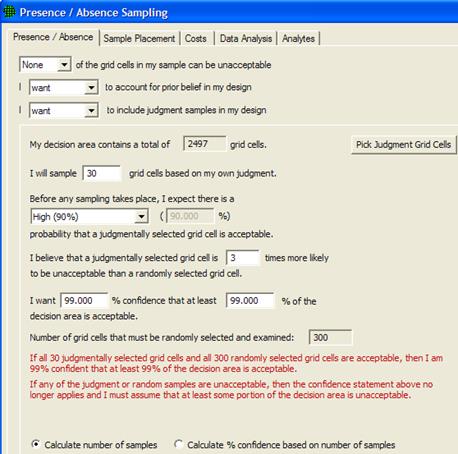

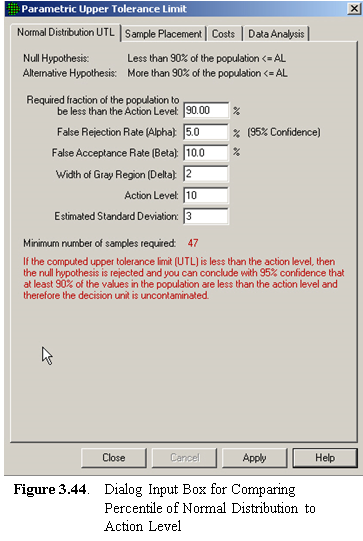

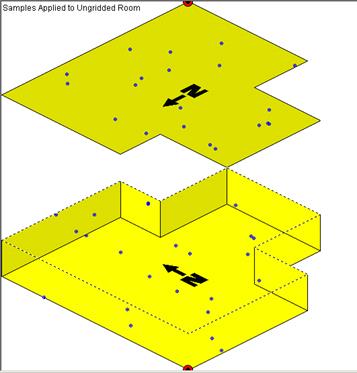

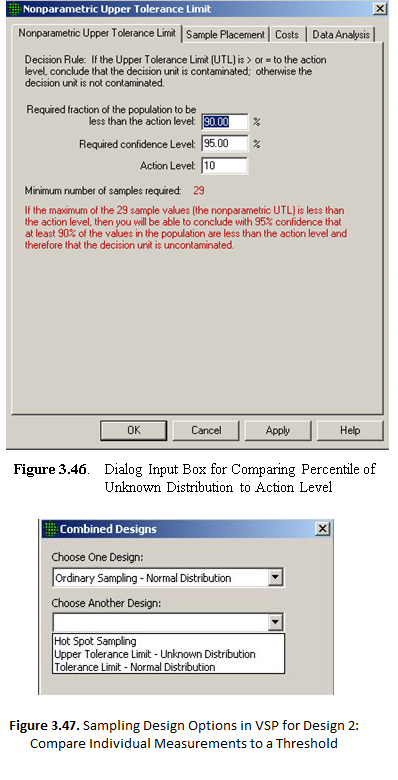

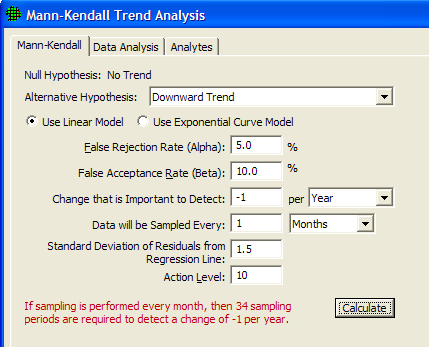

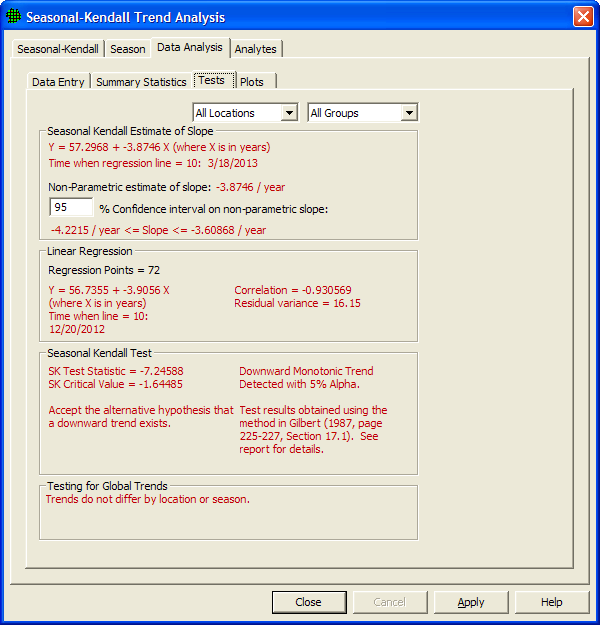

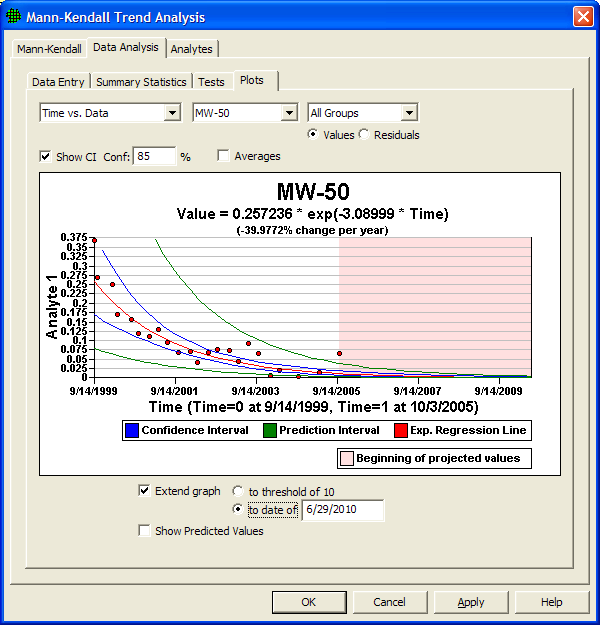

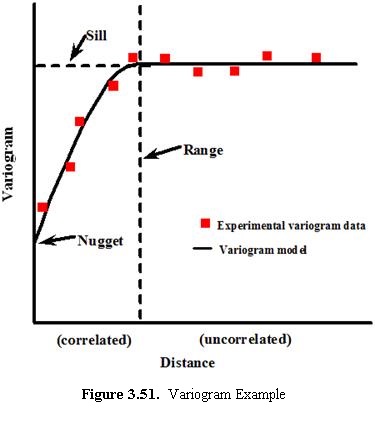

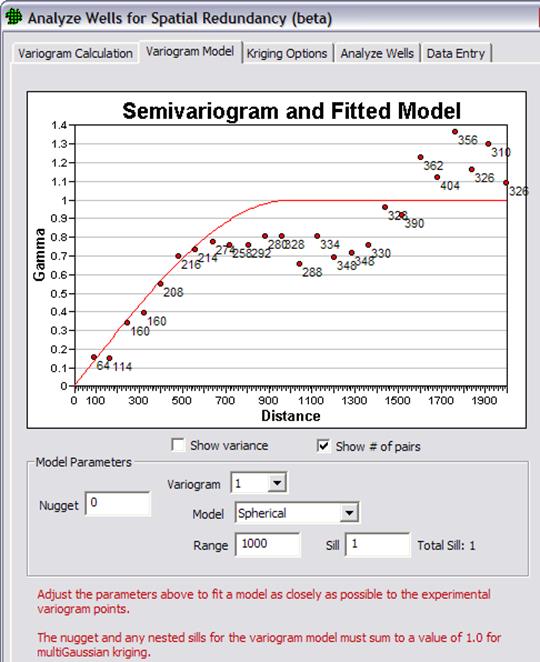

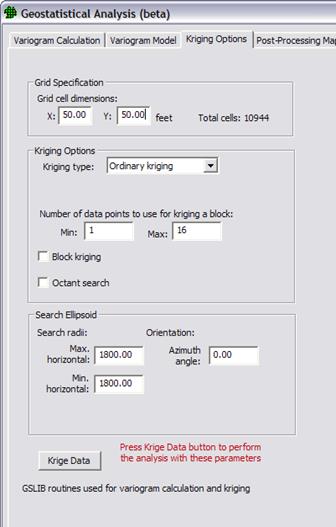

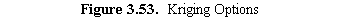

For detailed documentation on non-statistical sampling approaches, please refer to the VSP Help Topic Non-statistical Sampling Approach menu commands.